The Magnetix company

We have over 25 years of experience in the Automotive industry. We never stop and we constantly improve our qualifications, develop our technology, and raise our standards. As a leading European manufacturer of laminates, we ensure products tailored to the individual needs of many industries, but it is the automotive industry where we feel we are the experts, and where we see the greatest potential. Long-term contracts with automotive concerns allow us to boldly look towards the future and apply the acquired knowledge in innovative products.

We are ready for any challenge!!!

As a stable partner, we can have a real impact on the final product’s usability. The company’s policy focuses on constantly adapting to the customer’s needs, which guarantees achieving unique and customised solutions. Our qualified and experienced staff will ensure professional project handling. Our upholstery, headlining, and textile panels are a must in new car models.

Our offer

Quality

Our standards comply with the requirements of the automotive industry, which is confirmed by a quality management systems certification in accordance with ISO 9001 and IATF 6949.

Thanks to many years of experience in the automotive industry, we ensure support in the efficient implementation of new projects. Our internal laboratory allows us to implement a high level of control of the executed projects. Cooperating with accredited laboratories ensures the proper qualification process for an implemented product. A trusted supplier database allows us to ensure supply continuity, as well as the availability of the materials and services compliant with automotive standards.

Technologies

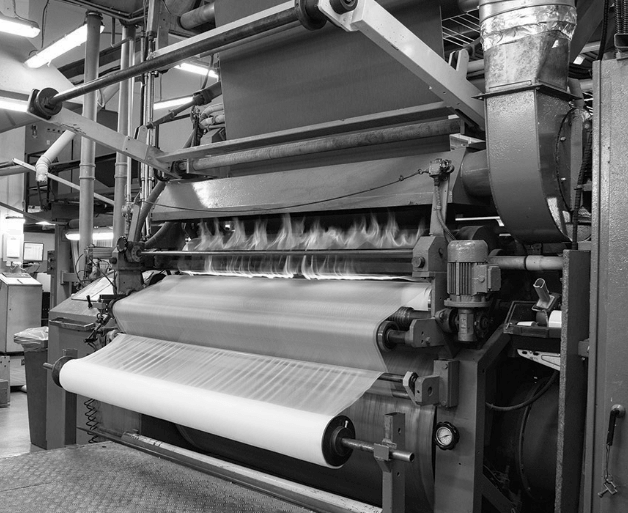

Flame

lamination

In this technology, the fabric is bonded with a polyurethane or polyethylene foam. This is done by applying heat from a flame to the foam, causing the glue to melt and bond the layers together. It is one of the fastest lamination methods, however, it requires the use of foam. Our machinery allows us to produce laminates of 208 cm in width and 16 mm thick.

Glue

lamination

Unlike flame lamination, glue lamination allows to join the material without using foam as an adhesive.

In this group we distinguish inter alia the hot-melt lamination. It is the newest and fully controllable process. This method uses a reactive adhesive. The adhesive is heated up prior to the lamination process and then applied to the layers by an engraved roller. As a result, the glue is distributed evenly, and the created textile arrangement does not undergo any further thermal treatment. Its physical features, such as thickness or stiffness, also do not change. The glue we use for lamination has an Oeko Pass certificate, and therefore, it is non-toxic and safe for health and for the environment.

Automated

cutting room

The MAGNETIX Textile Laminate Centre, in addition to its services of laminating, bonding, and gluing various types of fabrics, offers a modern, computer-operated cutting room.

We cut fabrics and knitwear, technical fabrics, decorative fabrics, laminates, and various types of foam. The automated cutter is a new generation machine, adapted to computer operated production. It is an innovative machine, and its usage in the production process, should be regarded as a new level of process and production quality. A comparative analysis has determined that the machine and its technology both bear the marks of innovation on a national scale, confirmed by the Opinion on Innovation issued by NOT (the Polish Federation of Engineering Associations).

Contact

MAGNETIX LAMINATION SP. Z O.O. SP.K.

Textile Laminate Center

Kaczeńcowa 18 street

Łódź, 91-214