Hot-melt adhesive lamination

Adhesive lamination is the most versatile method of joining materials, allowing the material to be joined without the use of foam as an adhesive. By using an adhesive, the laminated material becomes more resistant to tearing, washing and high temperatures, while maintaining the vapour permeability of the bonding layer.warstwy łączącej.

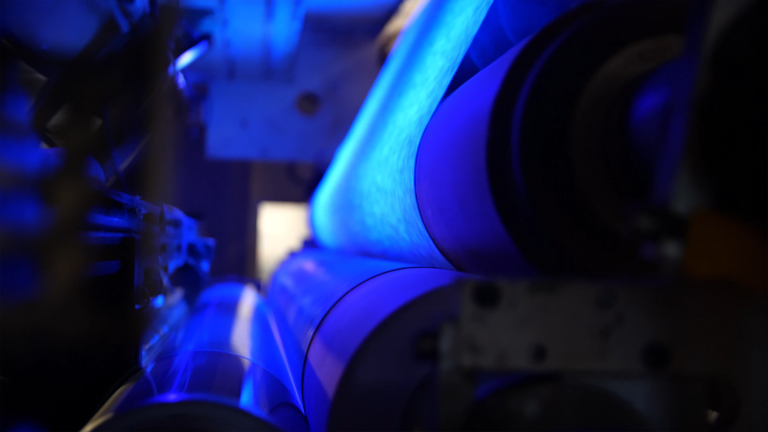

This state-of-the-art and fully controlled process uses a reactive adhesive that is suitably heated prior to the lamination and applied to the materials to be joined using an engraved roller. This ensures that the adhesive is evenly distributed and that the resulting textile system retains the properties of the individual components.

With adhesive lamination technology, our machinery allows the production of laminates up to 240 cm wide and 10-15 mm thick. Possible adhesive application ranges from 5 to 140 g/m2.

The adhesive we use for lamination is Oeko Pass-certified, meaning it is safe for health and the environment.

Other services

Adhesive lamination is the most versatile method of joining materials, allowing any material to be joined together.

The technology is based on bonding materials using polyurethane or polyethylene foam.

Flatbed lamination enables flexible bonding of materials with diverse properties – from fabrics to technical panels.

With the automatic cutting service, we are able to quickly deliver the parts ready for further processing, also sewing.

The embossing process allows attractive designs and also logos to be embossed on the die-cut parts.

A technology involving the wrapping of plastic or composite parts using pre-cut textile formats.

MAGNETIX LAMINATION SP. Z O.O. SP.K.

ul. Kaczeńcowa 18

91-214 Łódź, Poland

e-mail: magnetix@magnetix.pl

Tel: +48 728 356 576

Office: + 48 42 683 18 40w. 101

MAGNETIX LAMINATION Sp. z o. o. Sp. k. obtained a subsidy from the European Union for the project “Implementation of the company’s entry strategy into new foreign markets as a way to increase the export potential of the MAGNETIX company”.

The main goal of the project is to increase the competitiveness of MAGNETIX on the international market by building product brand awareness among foreign customers. The goal will be achieved by developing exports, acquiring new key customers and diversifying sales into new markets, promoting and building a competitive position of the brand on the foreign market.

The subject of the project will be to conquer new foreign markets, such as the Austrian and Dutch markets.

In accordance with the prepared Business Model, the project will implement the recommended activities:

– participation in the largest European specialized trade fairs as an exhibitor;

– participation in trade fair events as visitors;

– purchase of consulting services related to the search and selection of partners in target markets;

– preparation and production of individual materials promoting products on new markets.

The project will benefit employees who will be directly or indirectly involved in the implementation of the above tasks and people managing the enterprise. The project is aimed at potential customers of the company from foreign markets, where the goal is to obtain 10 commercial contracts.

#EUFunds

Project value: PLN 548,080.48

Amount of contribution from European Funds: PLN 378,754.79